An important innovation allows Almit MR-NH solder paste to obtain optimal results even for applications with an area ratio lower than 0.66.

In the automotive sector, electronic is more frequently directly placed at the power unit, wherefore a downsizing of the control units becomes necessary. Moreover, in module design, a high mix of "module sizes can be found more and more frequently. To guarantee a sufficient amount of solder paste for bigger modules, metal stencils with a thickness of up to 150 µm are used for these applications. This leads often to difficulties regarding the release properties of smaller modules, as e. g. of 0201-chip modules. In IPC guidelines, the area ratio value is recommended to be higher than 0,66 to maintain good release properties. The experience shows that an area ratio smaller than 0,66 leads to a worse soldering paste printing or worse release properties. However, there are many application examples where the area ratio is already now out of the recommended range, whereby deficient release properties occur. How can this issue be solved?

New standards for best results

New standards for best results

Almit’s lead-free solder paste MR-NH sets new standards here: Due to the special flux characteristics of MR-NH, optimal results can be guaranteed, even for applications with an area ratio smaller 0,66 -as well as regarding the print image as the release properties. Until down to an area ratio of 0,43, the solder paste MR-NH is compatible and enables hereby an application for nearly all stencils and modul combinations.

Taking a closer look at the surface resistance during an application with MR-NH, current standards are surpassed as well: MR-NH provides a significantly higher surface resistance which lays four potencies above the IPC norm.

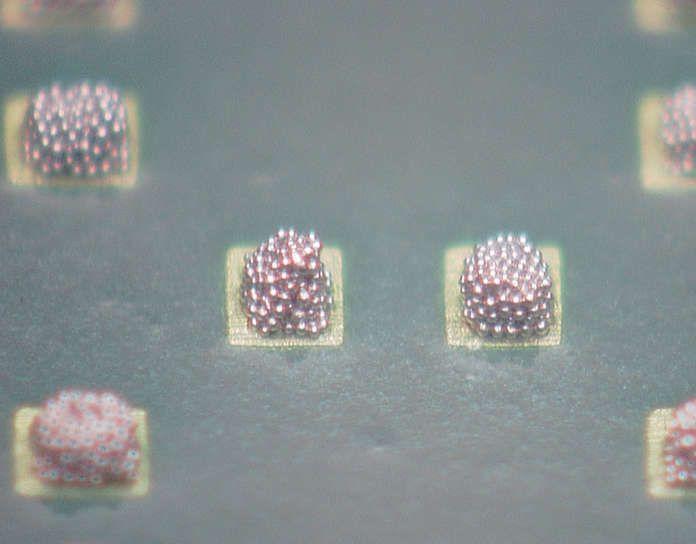

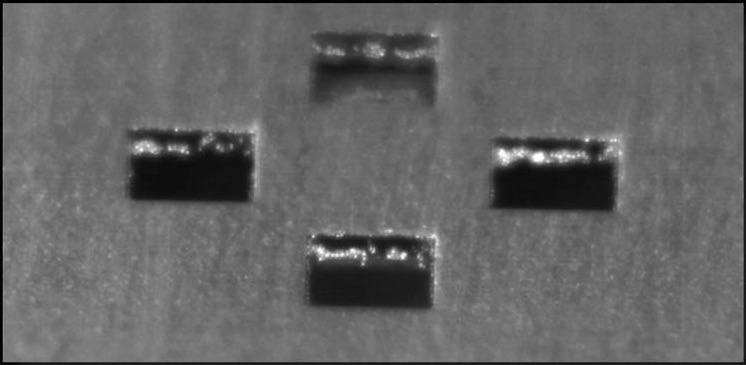

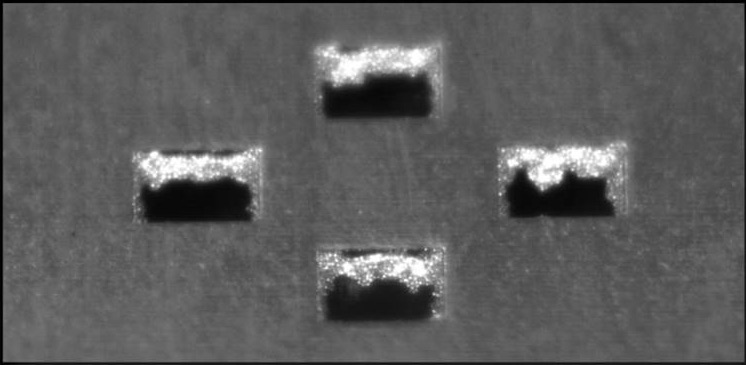

Different tests in comparison with a standard solder paste prove the quality advantage of MR-NH. In comparison tests regarding the release properties, MR-NH convinces with uniform, equally formed solder deposits. During the printing process with MR-NH, remarkably less solder paste stays sticked to the stencil than with a standard solder paste. (See Pict. 1)

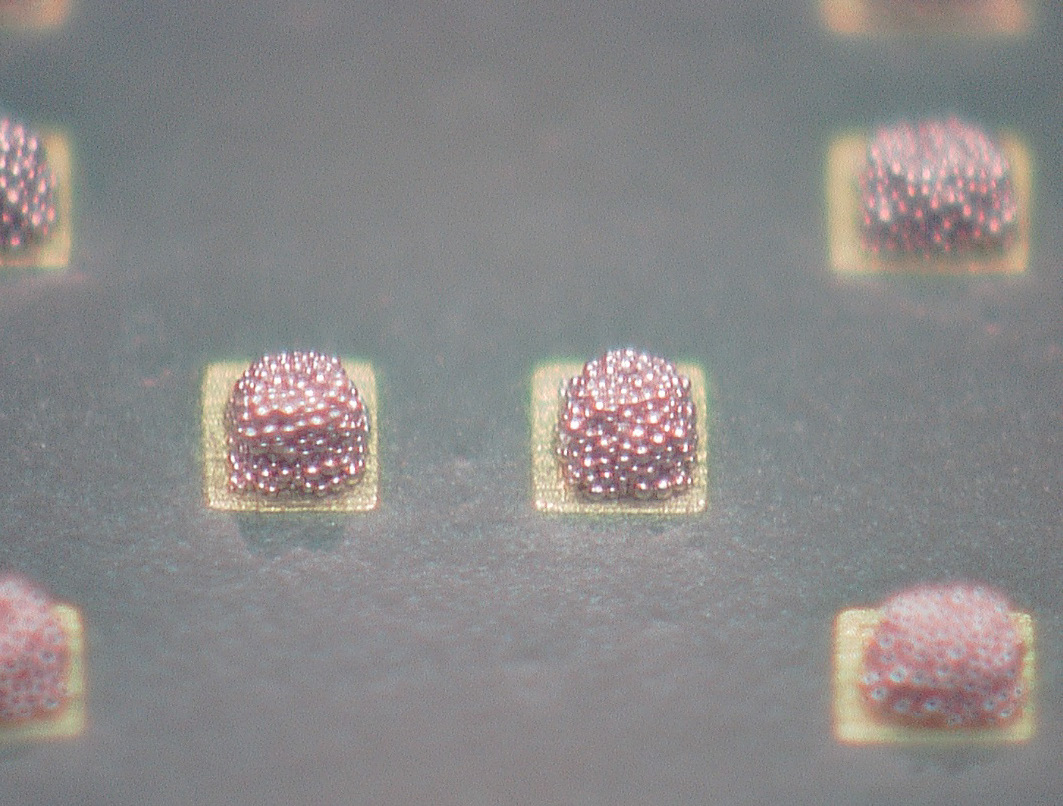

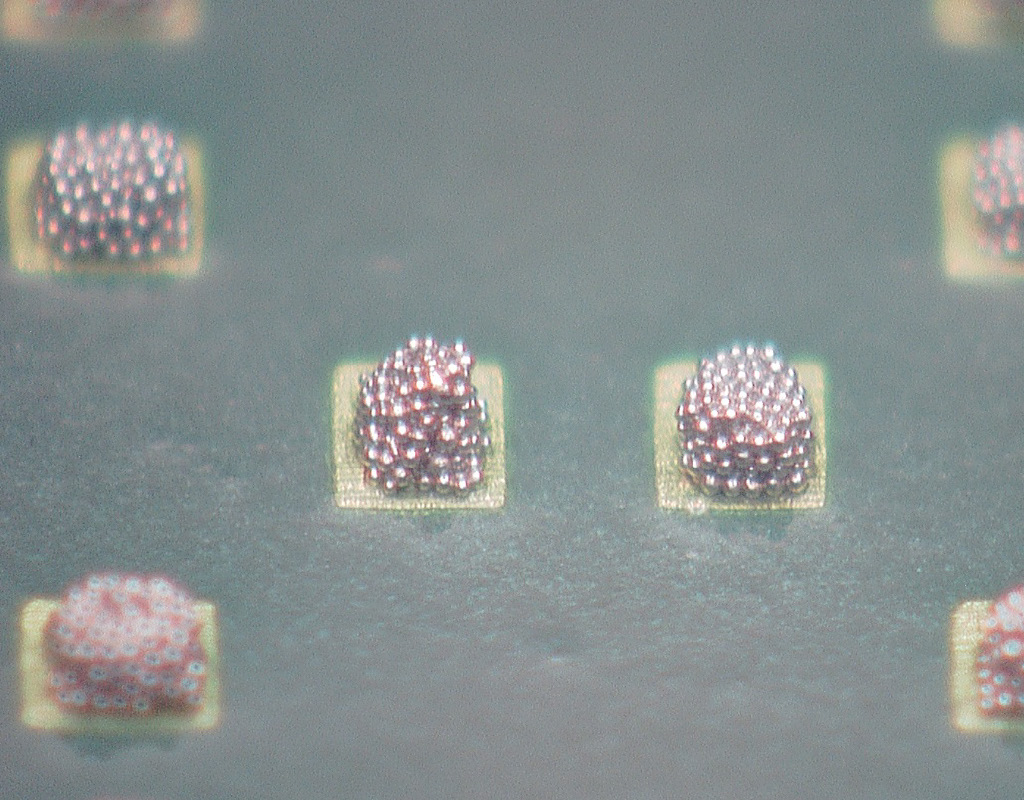

Also, in comparison of the printing contours and the printing characteristics, MR-NH lays ahead. MR-NH shows more equal, firmer contours as the standard product and provides even at a stencil thickness of t=150 µm an outstanding high volume rate. (See Pict. 2)

Pic. 2 - Comparison between MR-HN paste-on-chip deposition and traditional solder paste

Pic. 2 - Comparison between MR-HN paste-on-chip deposition and traditional solder paste

When MR-NH and a standard paste are compared at the same printing parameters, MR-NH is also right out in front concerning the improvement of yield. First customer tests show that a yield improvement of up to 20% can be achieved, as due to the good release properties the solder paste volume on the solder pads is remarkably higher. A customer who achieved so far at applications with a reference product a yield of 85%, reports a significant improvement thanks to the use of MR-NH: The yield increases to 98%.