CyberOptics Corporation demonstrated recently the MRS-Enabled SQ3000 with multi-process capabilities including 3D AOI, SPI and CMM applications at NEPCON South China at the Shenzhen Convention Center, last 28-29th August.

The SQ3000 offers a combination of unmatched accuracy and speed with the industry-leading Multi-Reflection Suppression (MRS) sensor technology that meticulously identifies and rejects reflections caused by shiny components and surfaces. Effective suppression of multiple reflections is critical for highly accurate measurement, making the proprietary MRS technology an ideal solution for a wide range of applications with exacting requirements.

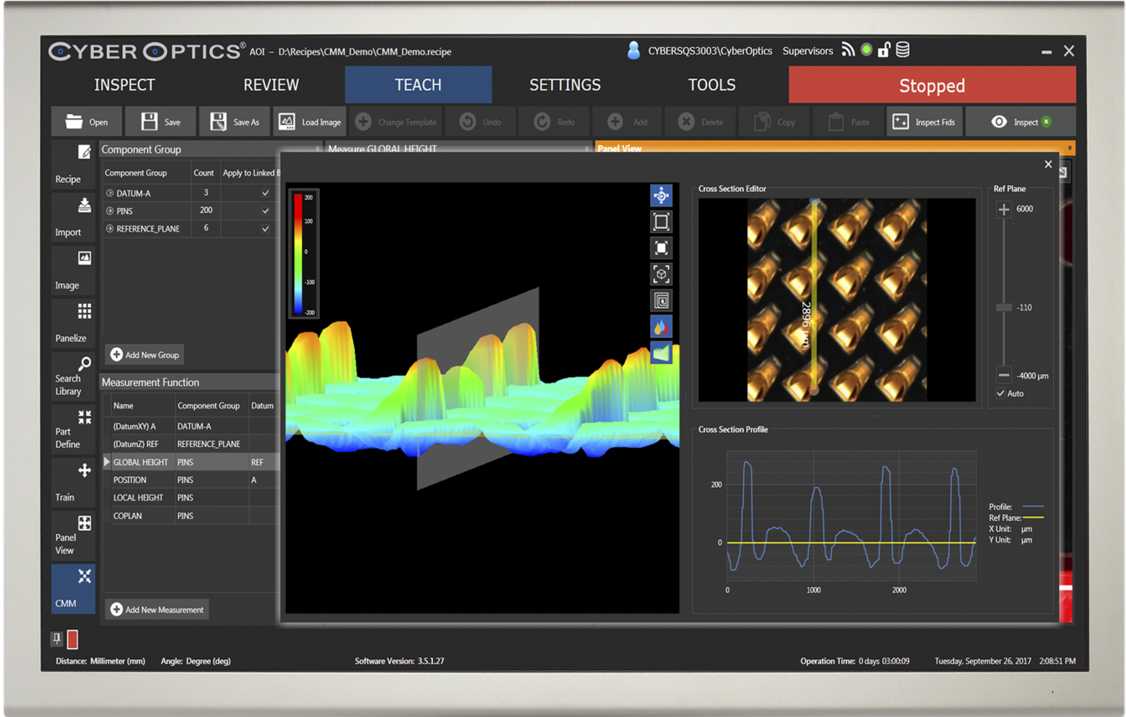

Perfect for AOI, SPI and CMM

The SQ3000, deemed best in class, has been widely used for 3D Automated Optical Inspection (AOI) and can now be used for 3D Solder Paste Inspection (SPI) for the best accuracy, repeatability and reproducibility – even on the smallest paste deposits. Combined with the award winning, easy-to-use software, solder paste inspection has reached a new level of precision for the most stringent requirements.

Additionally, the SQ3000 can be used to attain highly accurate coordinate measurements faster than a traditional Coordinate Measurement Machine (CMM) – seconds, not hours. The world’s first in-line CMM includes a comprehensive software suite for use in industrial metrology, semiconductor, microelectronics and SMT applications.

Customers worldwide are using the SQ3000 3D Multi-Function Inspection and Measurement system to improve yields, quality and operational efficiencies in their manufacturing facilities.